20 Years of Global Expertise

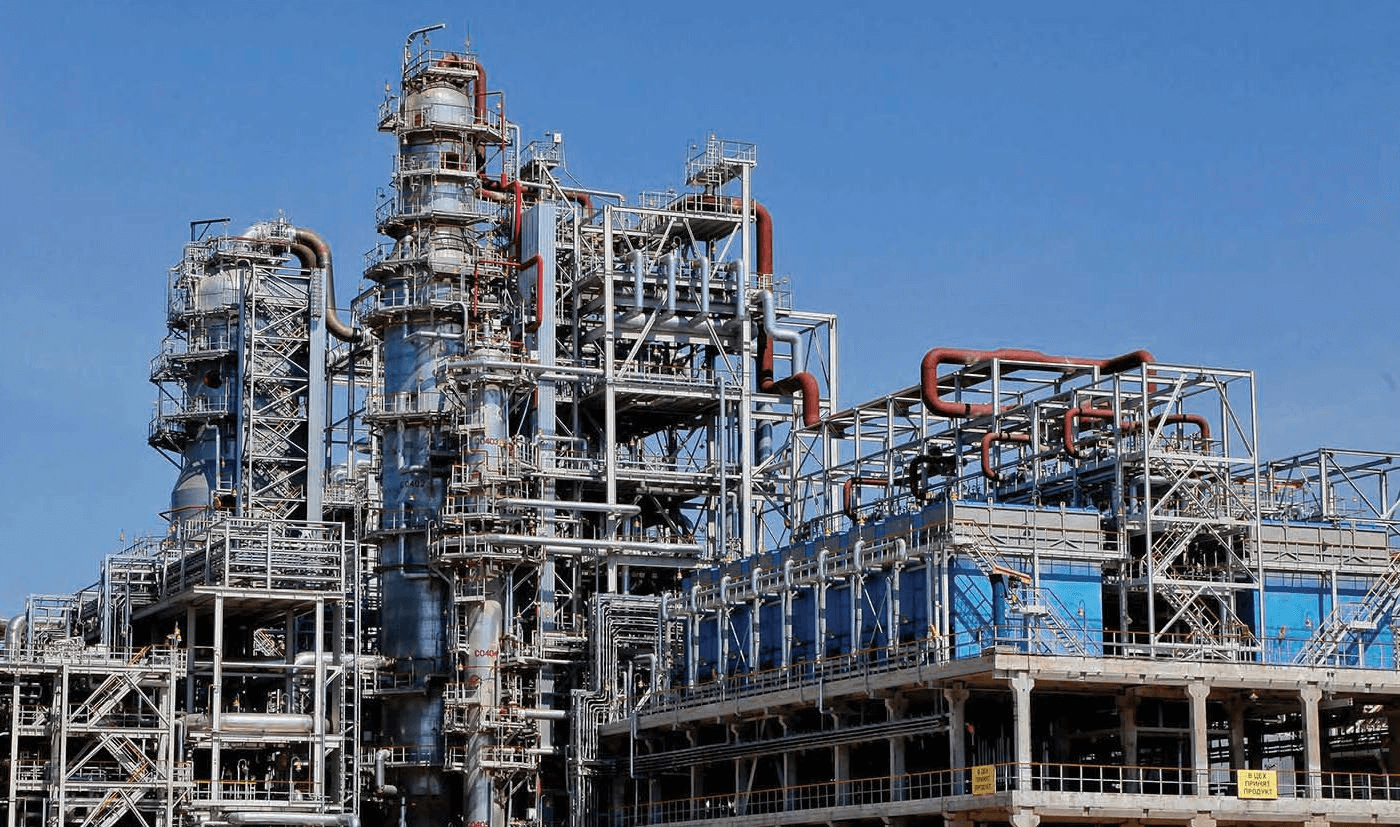

Project 1: Saudi Aramco / SABIC – Reformer Tube Integrity Management

- Role: Lead Asset Integrity Engineer.

- Challenge: Critical thinning and creep damage in high-temperature reformer tubes.

- Solution: Implemented specialized NDT and RBI intervals to prevent catastrophic rupture, ensuring 100% uptime during peak production cycles.

Project 2: TurkmenGaz – SRU Waste Heat Exchanger Rehabilitation

- Role: Integrity Team Lead.

- Challenge: Severe tube-end thinning and leakage in a Sulfur Recovery Unit (SRU) Waste Heat Exchanger with internal refractory lining.

- Solution: Managed a complex “Dry Mechanical Cleaning” and RFET (Remote Field Eddy Current) inspection to identify failing tubes without damaging the sensitive combustion chamber refractory.

Project 3: ADNOC / OQ – On-Stream Tank Bottom Assessment

- Role: Asset Integrity Consultant.

- Challenge: Potential floor corrosion in massive crude storage tanks with no scheduled downtime.

- Solution: Deployed Pulsed Eddy Current (PEC) for annular ring inspection and robotic crawlers for shell thickness mapping, providing an API 653 compliant audit without taking the tanks out of service.

Project 4: BAPCO / Qatar Energy – FFS Assessment on Aged Pressure Vessels

- Role: Senior Integrity Engineer.

- Challenge: Discovery of localized pitting and hydrogen-induced cracking in aging vessels.

- Solution: Conducted Level 2 Fitness-For-Service (FFS) assessments to calculate remaining life and re-rate operating pressures, saving millions in replacement costs.